milling machine parts and functions pdf

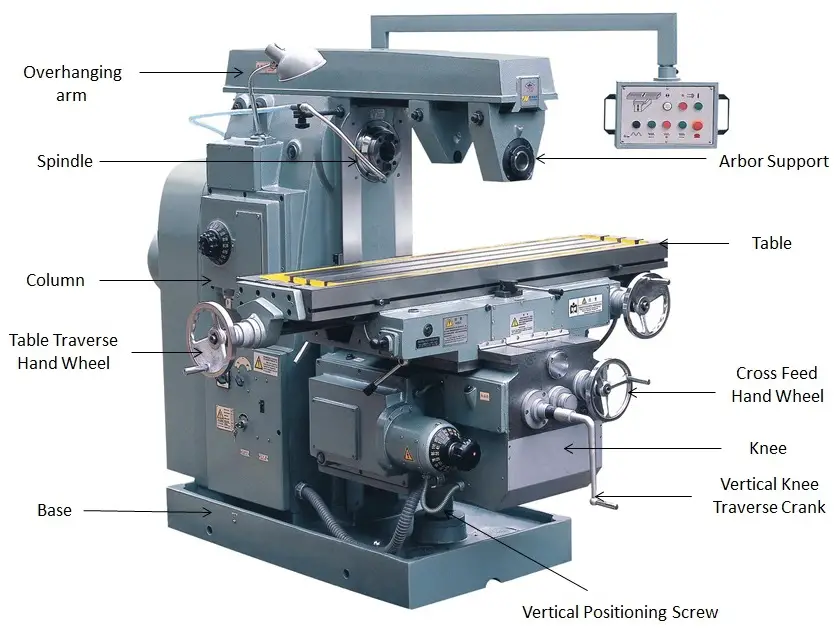

Plain hori- zontal universal horizontal and ver- tical. The columns of the machine will contain an oil reservoir to supply the lubricant to the spindle and help it stay smooth.

How To Use A Milling Machine Safely Free Step By Step Guide

High production of rotational parts.

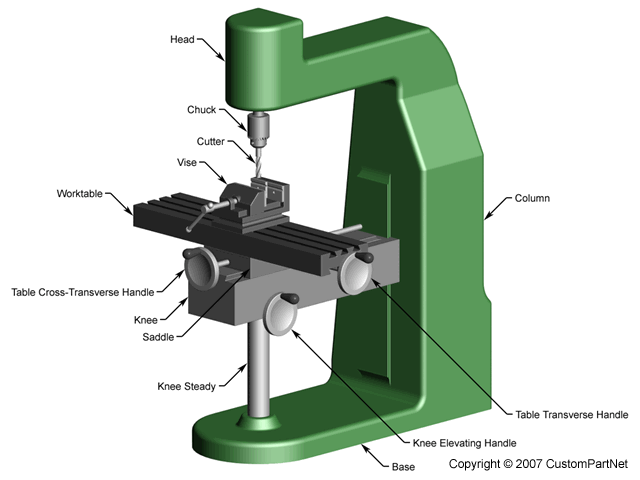

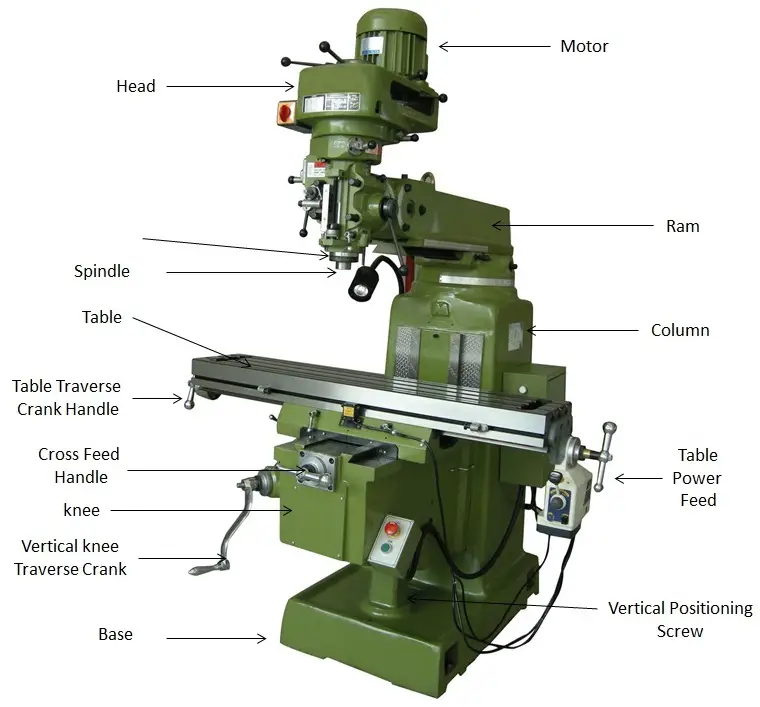

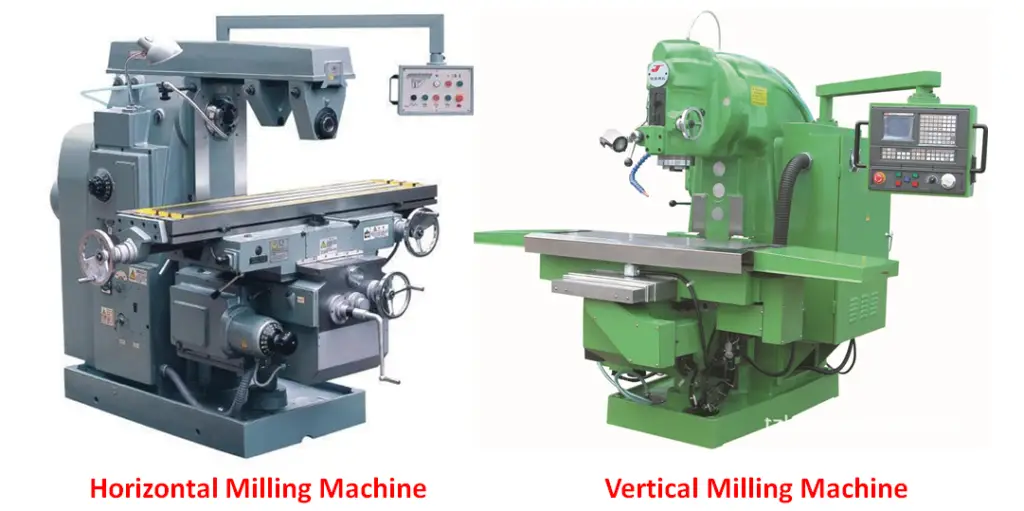

. For instance if a lot of material has to be removed by the cutters or there is less of a need for accuracy - a horizontal milling machine is chosen. There are various parts of this machine to know these parts you can see the description about 24 parts of the milling machine and their functions that are written below. The milling machine consists basically of a motor driven spindle which mounts and revolves the milling cutter and a reciprocating adjustable worktable which mounts and feeds the.

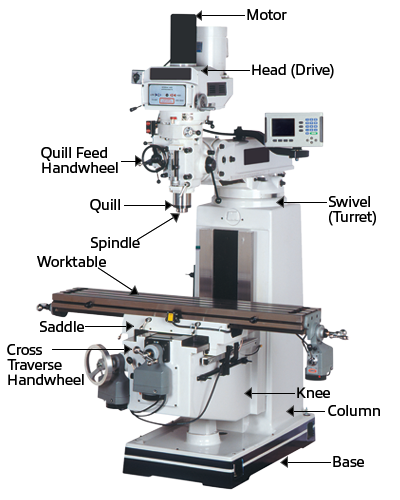

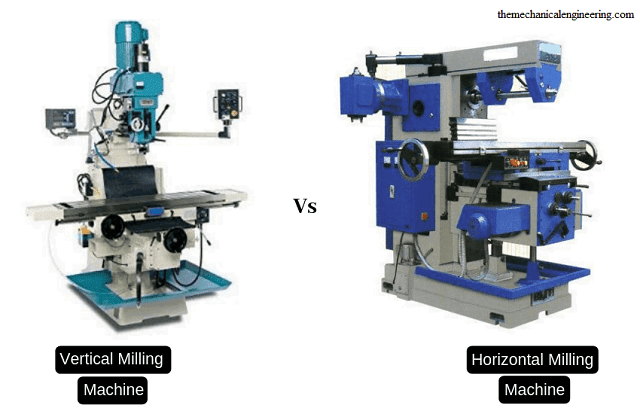

Most widely used of all milling machines is the horizontal knee-type shown in Fig. The type of milling machine most commonly found in student shops is a vertical spindle machine with a swiveling head. Care and Maintenance 4 Selecting Speeds and Feeds.

Vertical Milling Machine This study guide will cover the major working parts functions and machining techniques that can be foundused on most vertical milling machines. The milling machines knee rides up or down the column on a rigid track. Use of Cutting Fluids 4 Machining Operations 4 Other Operations 4 Setup Operations.

Bar Machine Similar to chucking machine except collet replaces chuck permitting long bar stock to be fed through headstock At the end of the machining cycle a cutoff operation separates the new part Highly automated the term automatic bar machine is often used Applications. 36 A SERIES MILLING MACHINE ACCESSORIES NEW NEW NEW NEW NEW NEW A34 Machine V ise for Shaping Milling Use VSM-A31 NC Hydro Machine Vice VNC-A33 Precision pneumatic. The column with lubricant.

The source of energy. These parts and angles in available in a great variety of shapes and sizes for varioussome form are common to all cutter types. Main Parts and Its Working Principle Types of Milling Machine Operations Plain Milling The plain milling is the most common types of milling machine operations.

The cutter rotates at high speed and because of the many cutting edges it removes metal at a very fast rate. The reinforcing ribs inside the bed are arranged reasonably and have. The main part of the milling machine starts with the base of it and the columns of it.

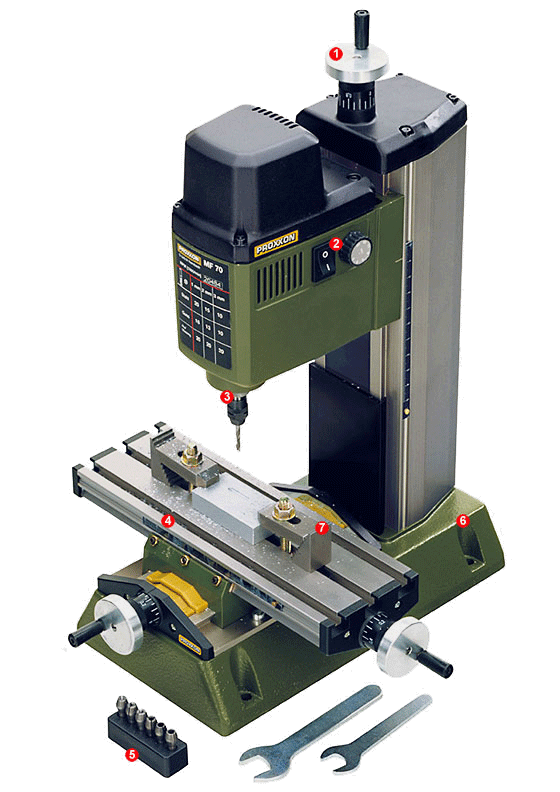

This machine can hold one or more number of cutters at a time and rotates at high speed to remove the metal at. These keys are universal and can be. These are some important parts of a benchtop milling machine that you need to know.

The term horizontal knee-type is de-. Cutting Tools and Holders. Horizontal Milling Machine Parts and Functions.

Soft keys are used on some machines. Parts potentially drawing the operator close to or into the cutter or spindle. Environmental Health Safety 135 College Street 203-785-3550 ehsyaleedu.

Vertical Milling Machine Parts and Functions. Typical CNC milling machines are divided into six parts that is bed milling head worktable cross feed part lifting platform and cutting oil cooling circulation system. We compile them from the top to the bottom as the following.

It is the most important machine in the tool room as nearly all the operations can be performed on it with high accuracy. This study guide has been designed to directly represent the questions that will be found on the open book written assessment and as an aid for the hands-on usability assessment. 7 Major Parts of A Benchtop Milling Machine.

Of the kneetype and bed-type milling machines attachments and accessories. CNC milling machines perform same functions as manual and creates arcs contours and 3D surfaces CNC milling machines can produce complex part surfaces that would be. 2 The universal horizontal milling machine also differs from the plain horizontal milling machine in that it is of the ram type.

Types Working Principle Operations Specifications Applications Advantages and Disadvantages PDF Hello Readers in todays article we will discuss the Planer Machine in brief along with its Definition Parts. The explanation for the parts of horizontal milling machine is as follows. Rapidly create designs from simple straight lines to complex geometric shapes w Xometry.

The electric energy from the outlet is converted into motion and the motion will spin the cutting tools. A milling machine is a machine tool that cuts metal as the workpiece is fed against a rotating multipoint cutter. Although there are several other types of milling machines shown is the vertical milling machine.

Knee-type milling machines are di- vided into three classes. Its function is to support various arbors. I on the opposite page.

Ad We support 3-axis 4-axis 5-axis as well as right angle milling capabilities. The vertical milling machine is a precision tool used for shaping and fabrication by the removal of stock. 219 Milling machine cutter and work-piece position Milling machine cutter and workpiece position The milling is a process of metal-removing by feeding the workpiece passes through the rotating multipoint cutter.

The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutterThe metal removal rate is higher very high as the cutter has a high speed and many cutting edges. Ie the milling machine spindle is in a swivel cutter head mounted on a ram at the top of the column. A heavy vertical positioning screw beneath past the milling cutter.

The following is a brief introduction of the role of cnc milling machine parts and components. This part is a part that has a function as a table stop on the machine. Operate machine The parts of a machining center control panel.

A milling machine removes metal by rotating a multi-toothed cutter that is fed into the moving workpiece. The column is the part of the machine body that serves as. A fixture is a work holding device fastened to the table of a machine or to a.

Table power feed is to adjust the table using power by rotating the available lever. The milling cutter rotates at a very high speed because of the multiple cutting edges it cuts the metal at a very fast rate. MILLING is the process of machining flat curved or irregular surfaces by feeding the workpiece against a rotating cutter containing a number of cutting edges.

Milling is the machining process in which the removal of metal takes place due to the cutting action of a rotating milling cutterIn a milling machine the cutter is rotating due to workpiece is fed against itThis machine can hold more than one tool at a time. The milling machine is excellent for. The spindle can.

Milling Machine Operations Page 23 of 37 MILLING MACHINE ACCESSORIES A wide variety of accessories which greatly increase its versatility and productivity are available for the milling machine. To the axis of the milling machine spindle permitting workpieces to be adjusted in relation to the milling cutter. Its the casting part of the machine that supports the machine to stand on and work.

Plain milling is performed to produce a plain flat horizontal surface parallel to the axis of. The diagram of cutting operation is shown below. The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint.

These accessories may be classified as fixtures or attachments.

What Is Milling Machine Operation Parts And Types Mechanical Booster

What Is Milling Machine Operation Parts And Types Mechanical Booster

What Is Milling Parts Operations And Types Of Milling Machine Youtube

Difference Between Horizontal And Vertical Milling Machine Mechanical Booster

Msc Industrial Supply Co Tech Essential Mill Machines

Milling Machine Parts Types Operations Milling Cutter Pdf

Vertical Milling Machine Parts In Hindi Basic Youtube Vertical Milling Machine Milling Machine Parts Milling Machine

Difference Between Horizontal And Vertical Milling Machine Notes Pdf

Horizontal Milling Machine Cad Cam Engineering Worldwide

Horizontal Milling Machine Cad Cam Engineering Worldwide

Tips For Buying Your First Milling Machine Hackaday

Warco Hv Horizontal Vertical Milling Machine Universal Industrial Mill

Milling Machine Types Working Parts Operations Cutting Parameter

Milling Machine Definition Parts Types Operations With Pdf

Bharat Industrial Universal Milling Machine Model Name Number 0 A 3 Rs 130000 Id 2838508448

Vertical Turret Milling Machine Model 3 With Dro M1tr Type Table Size 1250 X 254 Banka Machine